-

Крупнейший и самый современный производитель стиральных машин в мире

Крупнейший и самый современный производитель стиральных машин в мире -

-

-

-

Ссылки

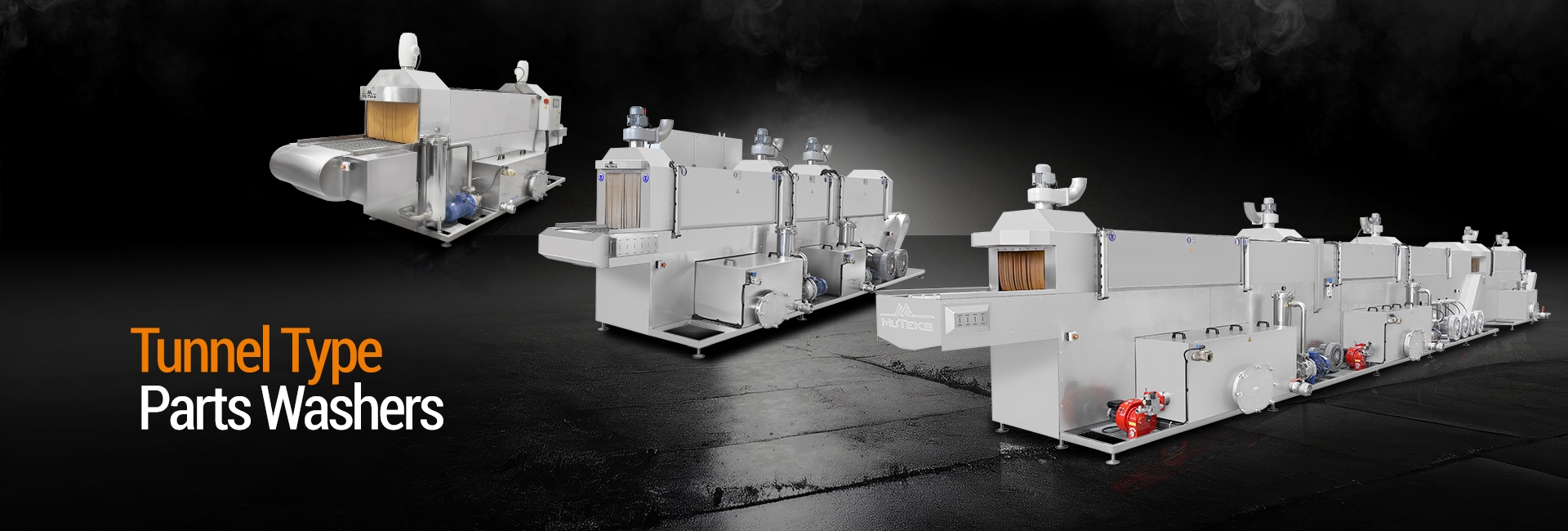

Промышленные стиральные машины

Руководство - Кабинет - Поворотная тележка - Конвейерный туннель - Ультразвуковой - Стиральные машины для погружения

Детали

Тест - Техническое обслуживание оборудования

Испытательные машины с головным блоком цилиндров с ручными и гидравлическими функциями, Вакуумные испытательные приборы, хонинговальные головки, вспомогательное оборудование

Детали

0+

Годовой объем производства

0+

Экспорт в страну

0%

удовлетворение

0+

Годы опыта

Почему Mu-teks?

Our company produces engine reconditioning machines since 1990. Mü -Teks , which also led to its competitors and has pioneered the development of the sector in Turkey.Our company designs with each machine user requests to consider keeping R & D efforts, that every new feature meets the different needs, therefore our products quality, with attention to practical use and performance, are shown in particular attention to the safety issues of ma- chine code division multiplexed channels of machines, with quality It has now become a well- known brand in many countries all over Turkey and the world. Since 1990, our continuously growing export line is an indication of this.

Блог Mu-Teks

Текущие сообщения в блоге

- 13.01.2020

Advantages of Parts Washing Machine

Buying industrial parts washing machines for your workplace gives you many advantages:

Reduces working time

Provides a safe working environment

Extends the life of equipment and parts

It saves you money.

- 11.01.2020

Ultrasonic Parts Washing Machines

Ultrasonic parts washing machines clean dirt with small, ultrasonic bubbles, explosions and solvents created by sound waves and vibration. These washers are gaining popularity because they offer environmentally friendly, safe and precise cleaning. You can perform ultrasonic cleaning as a standalone technology or include it in your existing aqueous or semi-aqueous cleaning systems. Ultrasonic cleaners allow users to clean even the most distant and tiny corners of their products. Ultrasonic cleaning is most often used for cleaning jewelery, heat exchangers, sensitive electronic parts, watches, weapons, precision instruments, and dental and medical instruments.

- 02.01.2020

Industrial Parts Washing Machine Efficiency

- 01.01.2020

Parts Washing Machines

- 20.12.2019